Main objective

The main objective is to demonstrate the technical feasibility of using eggshell as a secondary raw material in the manufacturing of ceramic wall tiles. For this purpose, an equipment will be developed to pre-treat the eggshell in order to separate the membrane from the shell itself, thus obtaining CaCO3 from a food industry waste. This will be a simple and low cost process.

Specific objectives

- To demonstrate the valorization of eggshell in the ceramic tile production process.

- To implement the concept of circular economy through industrial symbiosis between ovo-producing companies and ceramic companies (atomized powder producers and ceramic tile producers).

- To determine the economic benefits for both sectors.

- To develop a prototype for the pre-treatment of eggshell, which will separate the membrane from the shell through a simple and low cost process.

- To develop a new business model for ovo-producing companies as suppliers for the ceramic industry.

- To verify the absence of environmental impact in the treatment and subsequent use of eggshell.

- To confirm the environmental advantages of the use of bio-CaCO3 from the Life Cycle Analysis of the tiles.

- To transfer the knowledge acquired regarding the innovative valorization scheme to both the egg processing industry and the ceramics industry.

- To raise social awareness regarding the environmental problem caused by eggshells as waste, as well as the new scenario once the project is completed.

Shares

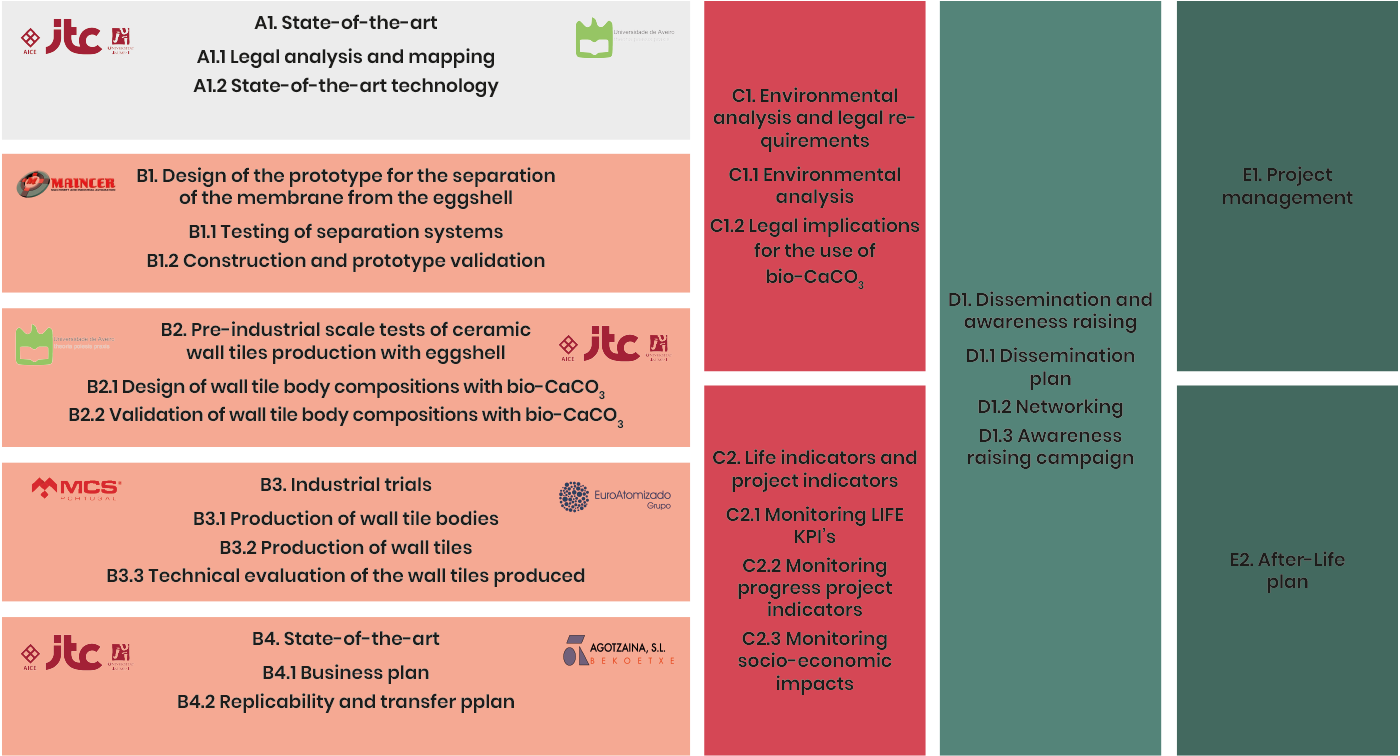

A1: State of the art

In this action, all the information necessary for the implementation of the project will be collected. On the one hand, all data on Spanish and Portuguese ovo-producers (companies and eggshell production) together with possible legal barriers will be gathered. On the other hand, a complete study of the technologies for eggshell membrane separation will be carried out, which together with the previous experiences of ITC-AICE, will help to define the prototype to be built in Action B1.

B1: Prototype design for eggshell membrane separation

This action is crucial to the success of the project, since the membrane must be effectively separated and removed to leave low or no organic matter content in the shell to ensure its successful use in the manufacturing of ceramic tiles.

In this action, different separation systems will be tested at laboratory scale to later incorporate them in the design of the prototype. The bio-CaCO3 obtained must meet a series of requirements from the chemical and behavioral point of view in the ceramic process, so it will undergo several tests to determine its viability for its use in ceramic tiles.

B2: Pre-industrial scale tests of eggshell ceramic tile production

The objective of action B2 is to demonstrate -at pilot scale- the valorization of the bio-CaCO3 obtained from eggshells with the prototype validated in action B1 in the production of ceramic tiles. Two main tasks are foreseen for the development of this action:

- Design of bio-CaCO3 tile compositions

- Validation of tile compositions with bio-CaCO3

B3: Industrial testing

Within the framework of this action, the suitability of the prototype built to separate the membrane from the eggshell will be confirmed, thus obtaining a secondary raw material for the ceramic industry: bio-CaCO3. On the other hand, the technical feasibility of using bio-CaCO3 as a secondary raw material in ceramic tiles will be confirmed.

The preparation of 50 tons of bio-CaCO3 for the manufacturing of at least 40 tons of atomized tile powder at ADM (Portugal) and another 40 tons of atomized powder at EUROATOMIZADO (Spain) is foreseen, which will result in the manufacturing of a total of 4000sqm of ceramic tiles with bio-CaCO3. These tiles will be characterized in order to confirm that there are no changes in their properties linked with the use of bio-CaCO3.

B4: Replicability strategy

This action comprises two sub-actions to ensure the sustainability of the project: On the one hand, a business plan will be developed for the companies designing a new business model (MAINCER and AGOTZAINA). On the other hand, a plan for the replication and transfer of the project results will be developed. This plan will include a set of activities aimed at replicating the project prototype in other ovo-producing companies and transferring the results to other ceramic companies and/or other sectors that use calcium carbonate in their compositions.

C1: Environmental analysis and legal requirements

This action will quantify the environmental benefits associated with the substitution of calcium carbonate mineral for bio-CaCO3 by performing a life cycle analysis of the new ceramic tiles. This will contribute to the development of action C2. The legal requirements associated with the use of bio-CaCO3 in ceramic tiles will also be studied to ensure the industrial implementation of this valorization strategy.

C2: LIFE indicators and project progress indicators

This comprises the measurement of different types of indicators that will make it possible to determine the effectiveness of the project’s results and contribute to establishing the impact of LIFE EGGSHELLENCE. Several types of indicators have been considered for this purpose:

- LIFE KPI’s: indicators established by the LIFE program

- Project progress indicators

- Socio-economic impacts

D1: Communication and dissemination of results

This includes all the actions aimed at effectively communicating the new strategy for the valorization of eggshell in the production of ceramic tiles and the suitability of the prototype developed for obtaining bio-CaCO3. Within the framework of this action, a Communication Plan will be developed, networking actions will be carried out with other projects and entities interested in implementing the project solution, and a “Stakeholders Advisory Board” will be established to detect the needs and interests of the main stakeholders.

On the other hand, several workshops and events will be organized for professionals (ovo-producing companies, ceramic companies) as well as citizens and public administrations.

E1: Project management

This includes all tasks aimed at ensuring the correct execution of the project.

E2: After-LIFE

This action is focused on the development of a plan describing the actions to be developed once the project is completed. These actions will guarantee the continuity and sustainability of the project. It will include actions for the dissemination and exploitation of the project results.

Stakeholders Advisory Board

An Advisory Board will be established in the first quarter of the project to identify the needs and interests of the egg processing industries. The entities involved are associations of ovo-producing companies and ceramic companies, as well as other companies which have shown their commitment to study the replication of the project.

Getting waste management authorities involved to be a part of this board and support the implementation of the solution developed in the project is part of the foreseen actions to be taken.

This group will meet at least once a year to discuss and share their needs and concerns.

This group will carry out the following actions:

- To advise project partners on changes in societal, policy and consumer priorities that may impact project objectives and outcomes;

- To review the project progress annually; taking into account stakeholder and end-user priorities to maximize project exploitation and benefits;

- To support the dissemination of the project results in their respective institutions and organizations.

The members of the Stakeholders Advisory Board are:

Sustainability

CONTRIBUTION OF THE LIFE EGGSHELLENCE PROJECT TOWARDS THE WORLD WE DREAM OF

The Life Eggshellence project contributes to some of the goals of the 2030 Agenda.

How does it do this?

Promote the circularity of the food sector.

It is estimated that egg production companies in Europe generate 150,000 tonnes of eggshell per year.

- Avoiding landfill.

- Transforming a waste product from egg production companies into a secondary raw material for the ceramics sector.Evitando su depósito en vertedero.

Promoting the circularity of the ceramic sector.

- Introducing a secondary raw material (bio-carbonate from eggshell) in ceramic tile compositions.

- Avoiding the extraction of mineral carbonate.

SUSTAINABLE DEVELOPMENT GOALS:

The Life Eggshellence project aims to modernise the infrastructure of egg production enterprises and convert them into more sustainable industries by installing a machine to separate the eggshell from the membrane. By using resources more efficiently and promoting the adoption of clean and environmentally sound technologies and industrial processes, all countries will be able to take action according to their respective capacities.

The Life Eggshellence project manages to considerably reduce the generation of waste from egg production companies through prevention, reduction, recycling and reuse activities by transforming eggshell waste into bio-carbonate. At the same time, a more sustainable management and efficient use of natural resources is achieved by the ceramic sector, as it allows the partial substitution of mineral carbonate by bio-carbonate from eggshell in the manufacture of ceramic tiles, reducingthe extraction of mineral carbonate. It also encourages national and international companies to adopt sustainable practices and incorporate sustainability information into their industrial process.

In this project we have partnered with technological centres, universities, egg production companies, ceramics, machinery and spray-drying companies in Spain and Portugal in order to avoid extracting virgin raw materials from nature, in this case calcium carbonate, and to reduce the deposit of eggshell generated by egg production companies in landfills. In this way, we establish alliances and help to respect the planet through a model of industrial symbiosis and circular economy, creating new products from waste. Furthermore, the project’s Advisory Board is a clear example of cooperation between companies and associations from both the egg production and ceramics sectors in order to make progress in terms of sustainability in both sectors.